Q:

When cleaning and Load ink the print head, no waste ink flows out. What should I do?

A:

Check whether the waste ink pump is working properly.

Check whether the print head and the ink cap are aligned left and right and front and back, and whether they are well sealed.

Step 1: Check whether the waste ink pump is working properly

Add the cleaning solution to all the ink stack caps, then click "Clean" to check if the cleaning solution inside the ink stack caps can reach the waste ink tank.

If the cleaning solution can be pumped into the waste ink bucket, it indicates that the waste ink pump is working properly.

Refer to Steps 2 and 3 to check whether the print head and the ink stack cap are sealed properly.

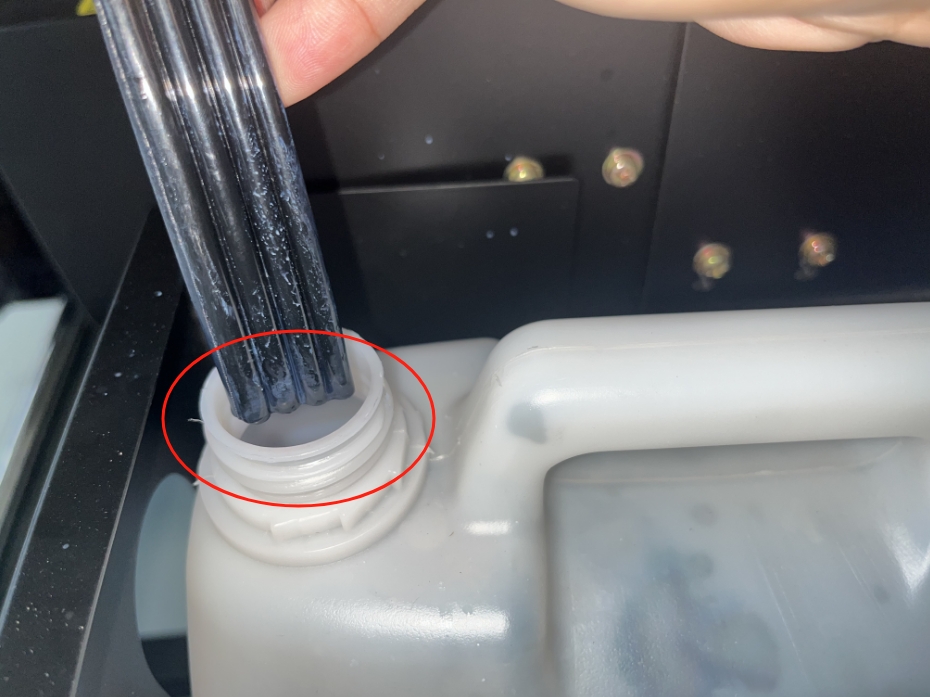

If the cleaning solution cannot be drawn to the waste ink bucket, check whether the ink tube at the bottom of the ink stack cap is connected properly.

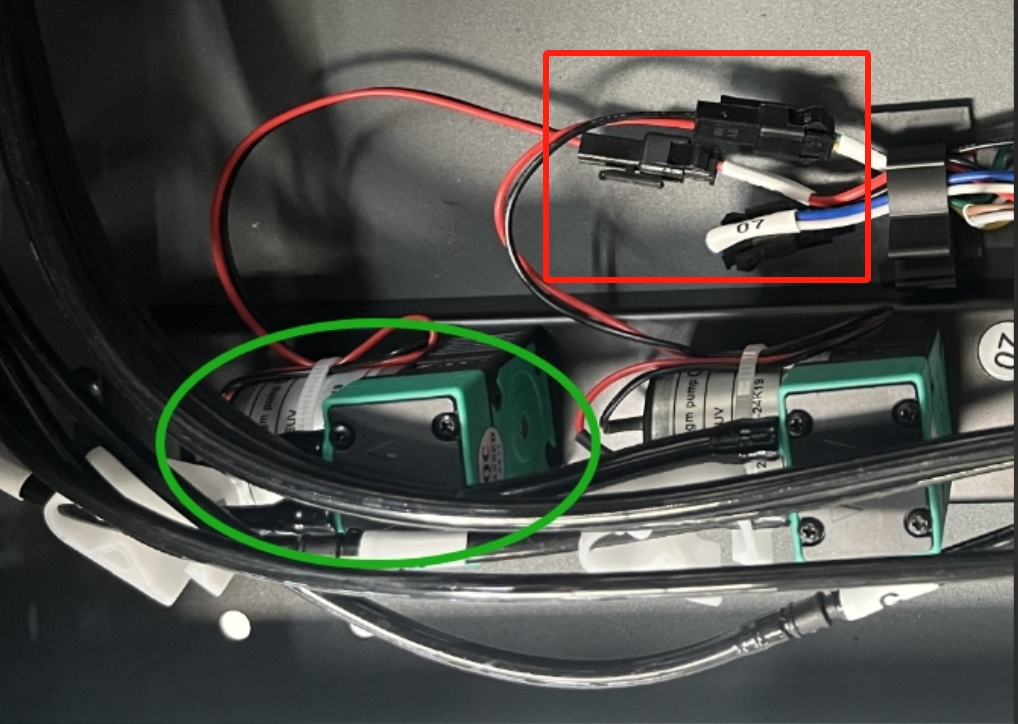

Check whether the waste ink pump is vibrating and working and whether the plug is loose.

If all connections are normal, it might be that the suction power of the waste ink pump is insufficient and it needs to be replaced.

Step 2: Check whether the print head and the ink stack cap are aligned left and right

The following are their standardly centered aligned pictures and videos:

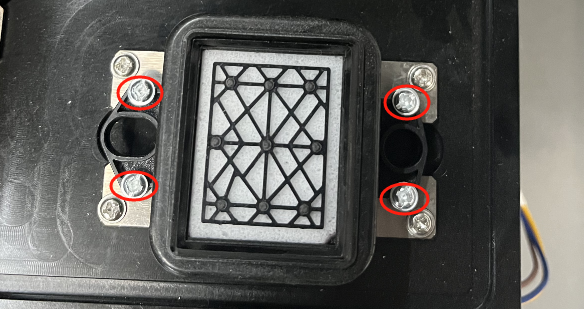

If one of the print heads and the ink stack cap are not centered and aligned, loosen the corresponding fixing screw of the ink stack cap, and then fine-tune the left and right positions.

Recheck, as shown in the figure:

If all the print heads and ink stack caps are not centered and aligned, loosen the fixing screws of the car origin sensor, and then fine-tune the left and right positions.

Restart the printer to take effect. Recheck as shown in the figure:

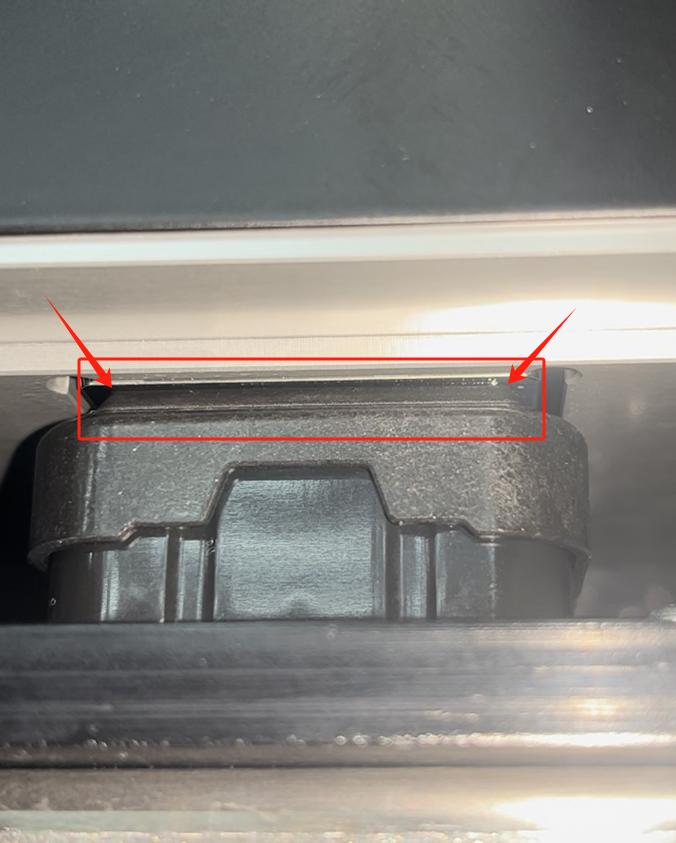

Step 3: Check whether the height of the print head and the ink stack cap is sealed properly

Generally, the best sealing state is achieved when the ink stack cap rises to touch the surface of the print head and then rises by about 1-2mm.

If the sealing height is incorrect, simultaneously modify the values of the "moisture retention ink stack height" and the "ink extraction ink stack height". Each fine-tuning should increase or decrease their "500" pulses simultaneously.

After making minor adjustments, click "Confirm Stroke" to check if the sealing height is appropriate. When the value increases, the ink stack cap rises; when the value decreases, the ink stack cap decreases.

After adjusting the sealing height to be appropriate, click Save.

Step 4: If all the above is confirmed to be normal, try using a syringe to hold the used ink tube by hand and see if the ink can be drawn out.

If the syringe can draw ink, it indicates that the seal between the print head and the ink stack cap is normal and the connection of the ink tube is normal. It may be that the suction force of the waste ink pump is insufficient and needs to be replaced.

If the syringe fails to draw ink and when the syringe draws the waste ink tube, it is very easy to pull the syringe without resistance.

It still indicates that there is no seal between the print head and the ink stack cap, or the connection of the waste ink pipe is loose. Repeat the check again.

If the syringe fails to draw out the ink, but when the syringe draws out the waste ink tube, there is a strong resistance when pulling the syringe.

This indicates that the print head nozzle might be clogged or there might be foreign objects blocking the waste ink tube. Check the status of the waste ink tubes and print heads.

Note: If the problem cannot be solved through the above methods, it is recommended to contact our relevant engineers for professional services.

If you have any questions, please contact the relevant personnel.

Add: No.6-2, Jinhua Zhong Road,Zhongshan

Tel: 86-760-88667090

Fax: 86-760-88667096

E-mail: market2@titanjet.com.cn

betty@titanjet.com.cn

he@titanjet.com.cn